What is Photoresist in Semiconductor Industry?

The photoresist market has been expanding since 10 years. According to statistics, the average annual composite growth rate of this value is about 5.4% in 10 years. So, what is the photoresist with such a broad market prospect? Let‘s get to know.

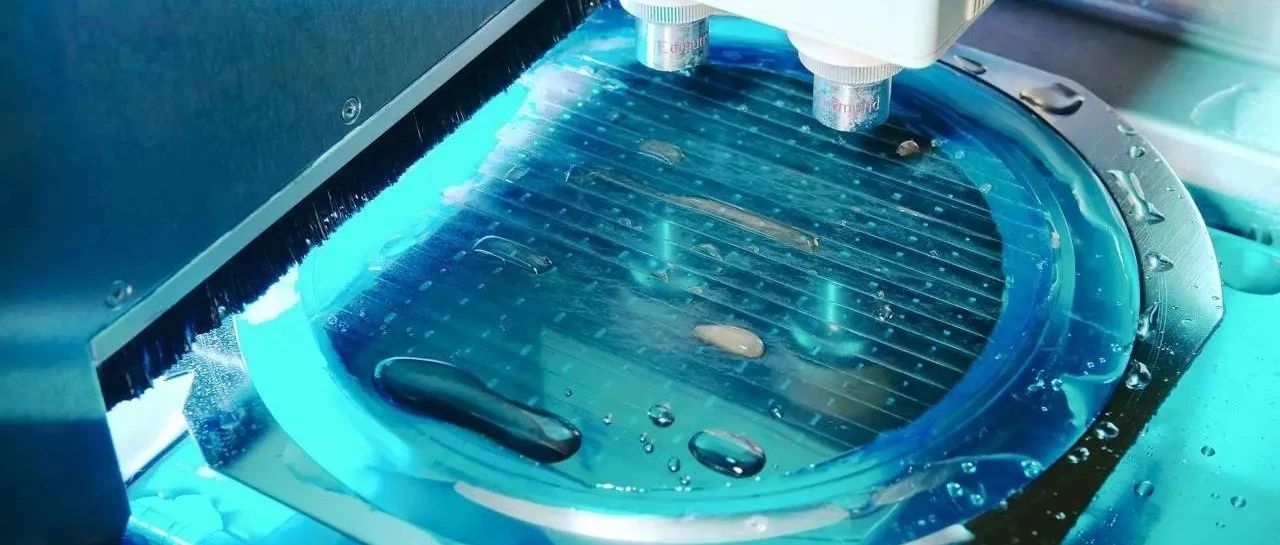

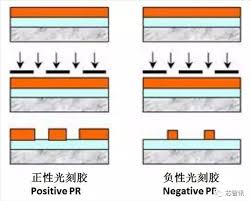

Semiconductor photoresist is a kind of graphic transfer medium which uses photochemical reaction to transfer the required fine graphics from mask plate to substrate by lithography process. The principle of semiconductor photoresist is to use ultraviolet light, excimer laser, electron beam, ion beam, X ray and other light sources to change its solubility. In the micro-machining of integrated circuits and semiconductor devices, photoresist is outstanding. At the same time, in the plate display, LED,PCB printing double circuit board process, photoresist also occupies a place.

The main components and solvents together form photoresist. The main components include resin, monomer, photoinitiator and additive. Resin and monomer occupy a great proportion, the general resin will occupy 50-60% of the main components, and the monomer is 35-45%. Solvent is the largest component in photoresist, which can dissolve all components of photoresist together and is an important medium for subsequent photoresist chemical reaction. The above is all about the operating mechanism and composition of photoresist.