The test purpose and application of UV aging test chamber

Test Purpose:Millions of dollars in economic losses are caused each year as a result of the destruction of materials by light and humidity. Ultraviolet aging test chamber can reproduce the damage caused by sunlight, Rain Water and dew. Ultraviolet aging tests can reproduce outdoor aging effects for months or years within days or weeks.

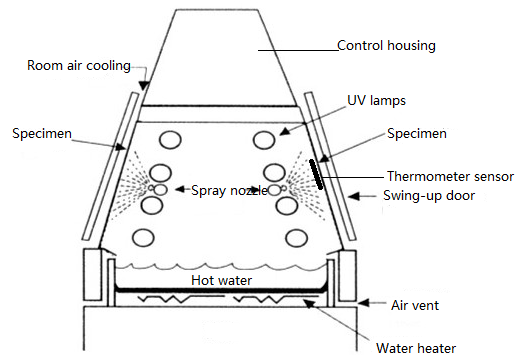

Ultraviolet aging test was carried out under the condition of high temperature control and alternating cycle of ultraviolet light and humidity. Fluorescent ultraviolet lamp is used to simulate sunlight, the chamber simulates dew and rain water through condensation or spray. The aging types of materials include discoloration, loss of light, powder, cracking, crack, atomization, foaming, embrittlement, strength decline and oxidation.

Usually, uv lamp can be divided into UVA and UVB. The UVA-340 lamp can simulate the short-wave ultraviolet light in the sun, that is, the wavelength range from 365nm to the solar cutoff point 295nm. However, the shortwave ultraviolet light produced by UVB-313 lamp is stronger than the solar ultraviolet radiation on the earth‘s surface, which can accelerate the aging of the material to the greatest extent. However, the lamp may cause unpractical damage to some materials. UVB-313 lamp is mainly used for quality control and research and development, or for testing materials with strong weather resistance.

Application:

The ultraviolet aging test chamber uses fluorescent ultraviolet lamp as the light source. By simulating the ultraviolet radiation, rain, condensation, temperature and humidity environment in the natural sun, the accelerated climate aging resistance test of the material is carried out in order to obtain the weather resistance of the material. Ultraviolet aging test chamber is suitable for non-metallic materials, organic materials (such as coatings, paints, rubber, plastics and their products) to test the aging degree of related products and materials under the changes of sunshine, rain, humidity, temperature, condensation and other climatic conditions, and to obtain discoloration, decolorization, powdering, cracking, blurring, embrittlement, strength decline and oxidation in a short period of time.

It takes only a few days or weeks for equipment to reproduce the damage that takes months or years to do outdoors. The damage mainly includes fading, discoloration, brightness decline, powdering, cracking, blurring, embrittlement, strength decline and oxidation. The test data provided by the equipment are of great help in the selection of new materials, the improvement of existing materials or the composition changes affecting the durability of products. The equipment can predict the changes that the product will encounter outdoors.

.jpg)