How to operate and maintan IP test chamber?

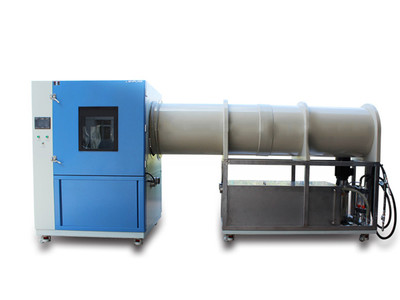

How to operate and maintain IP test chamber in order to extend its lifespan?IP test chamber is used to test the waterproof protection grade of automobile enclosure, accessories, lights,etc, it can provide realistic simulation of water spraying,continuous temperature change,pressure onto electronic products and their components during transportation,so as to evaluate the lifespan of these products in R&D stage.

.jpg)

Following is the maintenance methods:

The rain test chamber is exposed in the environment for a long time, the instruments, distribution boards and water circuits in the distribution room will gather dust, when wet air, it will cause equipment failure. In order to ensure the long-term stable operation of the equipment, please clean the distribution room once a month.

Warning: when doing this, please turn off the main power switch to avoid electric shock!) ,so pls first turn off the main power switch, open the distribution room cover, clean the dust of the electrical part with vacuum cleaner (or soft brush, preferably vacuum cleaner), finally cover the distribution room cover, and tighten the fastening screw.

Morever,there sre some points you should pay attention:

1. If the abnormal noise is heard in the operation, stop the machine and check, and then restart the machine after the fault is detected, so as to avoid affecting the service life of the equipment.

2. The transmission mechanism must be filled engine oil regularly. The speed reducer must be added with 20 # engine oil.

3. After the equipment is positioned, support the support frame to prevent the casters from being displaced after the equipment is tested.

4. Once the chamber is running for a long time. If the water-spraying hole is found to be blocked, pls tera down the pipeline,and wash it by the tap water,then assemble them again.

Following is the operation methods:

1. After the power is turned on, the machine will stop running when the control program setted is finished.

3, open the door handle of the chamber, and put the test sample on the sample shelf; Then close the door; note: the capacity of the sample shall not exceed 2/3 of test area;

4. According to the "TEMI880 Operating Manual", the test setting operation is carried out first, and then the test is entered automatically.

5. When you wanna observe the test inside the chamber,the door lamp switch can be turned on,you can see it through the window; the temperature and the humidity change in the test box can be displayed on the controller (if the humidity value is not required by the test, the humidity value is not displayed);

6. Open the door handle, and take out the test sample from the sample holder. View the tested samples and record the test conditions; this test is complete;

7. After the test is finished, turn off the power switch

www.climatechambers.com