Different dehumidification principles of electronic dry cabinet

The current electronic dry cabinet is divided into physical dehumidification adsorption technology and TE cooling dehumidification technology. What is the difference between the dehumidification methods of electronic dry cabinet, which one is better when storing items?Physical adsorption technology of electronic dry cabinet:

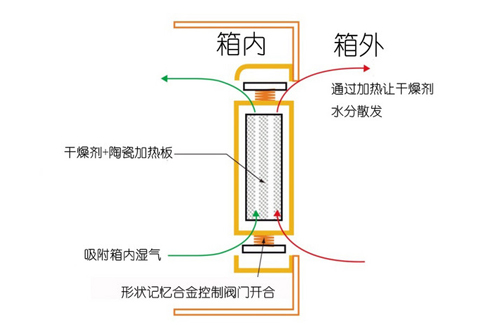

There is a high efficiency desiccant in the dry module of the electronic dry cabinet, and the high efficiency desiccant can absorb the moisture in the cabinet very quickly. When the moisture in the cabinet is absorbed, the ceramic heating plate in the dry module will begin to heat, and the heat can be transmitted to the desiccant to evaporate the moisture in the desiccant. At the same time, the shape memory alloy control valve opens and the evaporated moisture is emitted outside. The valve is normally closed and only when steam is drained.

TE cooling technology of electronic dry cabinet:

TE cooling is to condense the wet air inside the electronic dry cabinet into water droplets, and then drain these water droplets out of the cabinet through drainage pipes. The good point of the die-cutting machine is that it does not hurt the storage items, and the temperature does not heat up during dehumidification. The bad side is that when there is a power outage or failure, there may be a counter-tide situation, which damage the stored items.

The above two dehumidification technical principles are now the main dehumidification principle used by electronic dry cabinet manufacturers, according to the storage of items to choose their own suitable dehumidification and electronic dry cabinet.