Thermal Shock Chamber (3 zone type) aims to test products performance under continuous high low temperature cycles exposure, the purpose is to analyze and evaluate products safety performance and screen unqualified ones in early stage, it can finalize products chemical changes/physical damage caused by heat expansion and cold contraction principle, the test is mandatory from precise IC to mechanical parts.

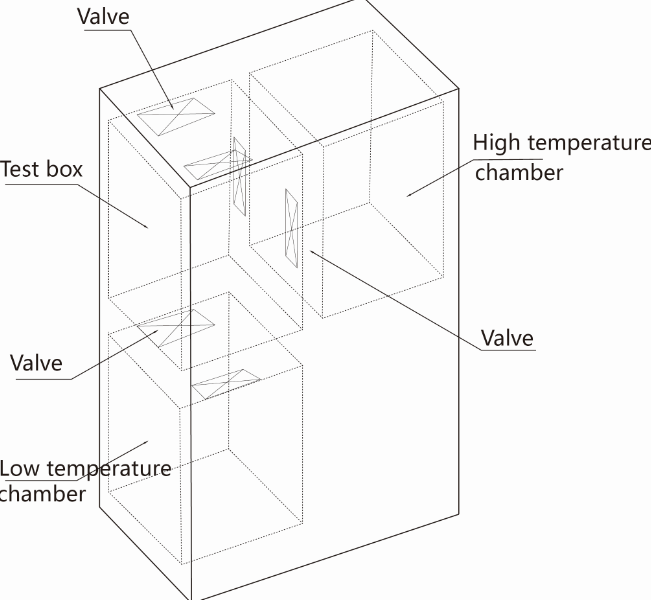

Structure

Application

.Plastic .Aviation parts .Military parts

Details

Controller

7” Programmable touch screen controller

3 Zone Thermal Shock Chamber

Related Technical Articles:

1.Climate Chamber Maintenance Overview

2.How to calibrate the climatic test chamber?

3.Quarterly maintenance of thermal shock test chamber

4.Temperature cycle chamber for semiconductor reliability test

5.The top three compressor brands for walk-in test chamber

6.Our visit to climatic test chamber distributors

7.How to inspect the temperature recovering time of thermal shock chamber?

|

Model

|

TS3-100 |

TS3-210 |

TS3-300 |

|

Interior Dim.

W*D*H(mm)

|

500*500*400 |

600*700*500 |

780*700*550 |

|

Exterior Dim.

W*D*H(mm)

|

1950*1150*1950 |

2100*1350*2200 |

2250*1350*2300 |

|

Preheat Room

|

Preheat Temperature

(Upper limit)

|

200°C

|

|

|

Heating Time

|

RT~+200°C /about 40min (unload) or customized

|

||

|

Precool Room

|

Precool Temperature

(Lower limit)

|

-75°C

|

|

|

Cooling Time

|

RT~-70°C /about 90min (unload) or customized

|

||

|

Test Area

|

Thermal Shock

|

-20°C,-40°C,-55°C~+150°C

|

|

|

Temperature Range

|

|||

|

Temperature Fluct.

|

≤±0.5°C

|

||

|

Temperature Bias

|

≤±3.0°C

|

||

|

Transfer Time & Recovery Time

|

≤15S & ≤5min

|

||

|

Material

|

Interior Material

|

Stainless steel (SUS304)

|

|

|

Exterior Material

|

Double side cold rolled steel with surface painting

|

||

|

Insulation Material

|

Superfine fiberglass wool / polyurethane foam

|

||

|

Refrigeration

|

Cascade refrigeration system, Germany imported “Bock” compressor

|

||

|

Controller

|

Programmable controller tailor-made for thermal shock chamber

|

||

|

Accessories

|

Over temperature protector, halogen light, cumulative timer,castors,etc

|

||

|

Safety Device

|

Overload protection: compressor over-pressure protection, over-current protection, short phase protection, water shortage protection, low voltage protection, independent over-temperature protection

|

||

|

Power Supply

|

AC380V 50HZ/60HZ or customized

|

||

| File Name : | Type: | Size: | Downloads: |

|---|---|---|---|

| Thermal shock chamber | 238.51 KB |